Ntlafatsa Sebetsa le ho Nepaha ka Mochini oa khatiso oa CNC Turret Punch

lihlahisoa tlhaloso

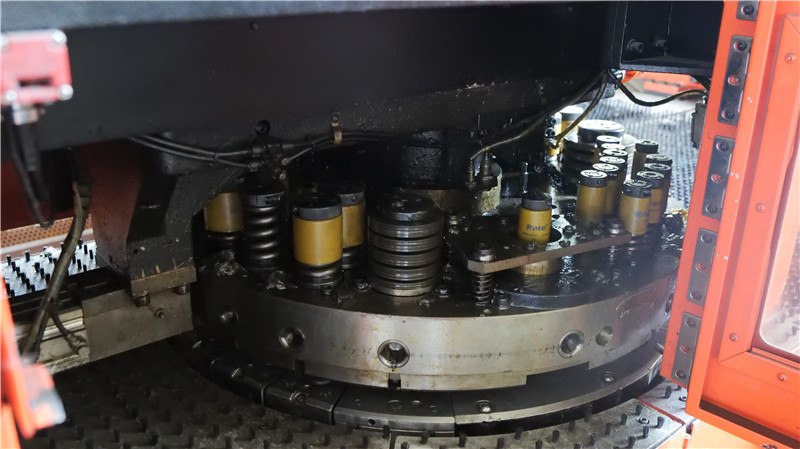

Mochini oa CNC turret punch oa mofuta oa WSD-S2030NT o sebelisoa haholo indastering ea ho lokisa lisebelisoa.E ka finyella litlhoko tsa sebopeho sa mefuta eohle e fapaneng ea thepa, 'me e ka finyella litlhoko tsa tlhahiso ka nepo ho latela boholo le bongata.Ka ts'ebetso ea eona e ntle ka nako e telele, bokhoni bo botle ba ho itšeha le nako e potlakileng ea ho fetola, punch e fetohile setho sa bohlokoa lethathamong la baetsi ba lisebelisoa tsa ho itšeha.Ho phaella moo, mochine oa WSD-S2030NT CNC turntable punch o boetse o na le sesebelisoa sa ho lemoha se hlokahalang ho netefatsa ho leka-lekana pakeng tsa torque, ho falla, lebelo le lintlha tse sa tšoaneng ts'ebetsong ea karolo ea mantlha.Thepa ena e loketse ka ho khetheha bakeng sa tlhahiso ea batch e mahareng le e nyane likarolong tsohle (joalo ka bongata ba likotoana tse 500 ~ 1000 sebakeng sa 2.4M * 1.2M ka poleiti e teteaneng ea 5mm).Ho bonolo ho kopanya ts'ebetso ea phallo (joalo ka welding / polishing / loading/download/test/sheet iron cutting/electronic welding), e ntlafatsa haholo ts'ebetso ea kakaretso ea tlhahiso, e etsa hore likarolo tsa 'mele li bonahale li khanya, li le monate ebile li tšoarella,' me li kopane le litlhoko tsa moreki bakeng sa tshebetso e ntle ka ho fetisisa

tlhahiso ea lihlahisoa

| Mohlala le tlhophiso | |||

| Mohlala | Setšoantšo sa WSD30422AI | NC2510NT | WSD—S2030NT |

| Sistimi ea CNC | FANUC Oi—PF | FANUC Oi—PF | Treo, UK |

| Stroke(mm) | 37 | 37 | 32 |

| Boemo ba ho nepahala(mm) | ±0.05 | ±0.05 | ±0.05 |

| Ho beha boemo bocha(mm) | ±0.03 | ±0.03 | ±0.03 |

| X-axis stroke(mm) | 2500 | 2500 | 2500 |

| Y-axis stroke (mm | 1250/1500/2000 | 1250/1500/2000 | 1250/1500/2000 |

| Ho sebetsa boholo ba leqephe(maemo a le mong)(mm) | 2500*1250/1500/2000 | 2500*1250/1500/2000 | 2500*1250/1500/2000 |

| Max.botenya ba ho sebetsa(mm) | 3.2 | 3.2 | 3.2 |

| Boima ba pampiri (kg) | 150 | 150 | 150 |

| Lebelo la ho tsamaya la Max.X-axis(mmin) | 120 | 120 | 120 |

| Max.Y-axis ho tsamaea lebelo(mmin) | 80 | 80 | 80 |

| Max.punch e otla ka lebelo la 25mm&4mm stroke(hpm | X:360 Y:360 | X:360Y:360 | X:400Y:350 |

| 5mm mohato 4mm stroke stamping speed(hpm) | 500 | 500 | 500 |

| Nako e phahameng ea ho phunya(cpm) | 920 | 920 | 1900 |

| Boholo ba bophara ba ho phunya(mm) | 88.9 | 88.9 | 88.9 |

| Setsi sa mosebetsi | 42 | 30 | 30 |

| Tlatsetsa | 3 | 3 | 3 |

| Palo ea lilepe tse laolehang | 5 | 5 | 5 |

| Tlhokahalo ea matla | 3 mohato 380V50HZ 46KVA | 3 mohato 380V50HZ46KVA | 3 mohato 380V50HZ 46KVA |

| Kakaretso ea boholo(I*w*h)mm | 45405200*2160 | 4540*5200*2000 | 6440*5200*2200 |

| Boima ba mochini(ton) | 16 | 14 | 17 |

1. Ho utloisisa CNC Turret Punch Presses

CNCMochini oa khatiso oa Turret PunchsKe mechini e tsoetseng pele ea boiketsetso e sebelisoang bakeng sa ho hatakela ka nepo liindastering tse fapaneng ho kenyeletsoa ho etsa likoloi, sefofane le litšepe.Mechini ena e na le turret e potolohang e amohelang mefuta e fapaneng ea likhetho tsa lisebelisoa ho sebetsana le mesebetsi e mengata ea litempe hantle le kapele.

2. Mochini oa khatiso oa CNC turret punch

Ts'ebetso ea setempe e qala ka ho lokisa litšoantšo tsa CAD kapa lifaele tsa moralo, ebe li fetoloa khoutu e baloang ke mochini ho sebelisoa software ea CAM.Ka mor'a hore khoutu e hlahisoe, e tla fetisetsoa mochine oa khatiso oa CNC turret punch bakeng sa ho bolaoa.

Lisebelisoa tse entsoeng ka hloko ka har'a turret li khethoa ka bo eona ho latela litlhoko tsa mosebetsi o mong le o mong oa setempe.Likhetho tsena tsa lisebelisoa li ka kenyelletsa mefuta e fapaneng ea litebele, li-dies, esita le lisebelisoa tsa ho etsa, ho holisa bokhoni ba mochini.

Letlapa la tšepe kapa workpiece e tiisitsoe ka thata holim'a bethe ea mochine, ho netefatsa botsitso nakong eohle ea ho hatakela.Sistimi ea taolo ea mochini ea CNC ebe e sebelisa khoutu ho tsamaisa punch hantle hore e tsamaisane le sebaka se lakatsehang sebakeng sa mosebetsi.

Sesebelisoa sa ho phunya se kentsoe ka matla a maholo ho phunya masoba ka nepo mosebetsing.Ho itšetlehile ka litlhoko tse khethehileng, mochine o ka etsa liketso tse ngata tsa ho phunya tse kang ho koala, ho teba kapa ho khabisa ka lebelo le tsotehang le ho nepahala.

3. Melemo ea CNC turret punch press

3.1 Ho nepahala le ho Nepaha: Likhatiso tsa CNC turret punch li fana ka ho nepahala ho phahameng bakeng sa liphetho tse tsitsitseng, tsa boleng bo phahameng.Litsamaiso tse tsoetseng pele tsa taolo li netefatsa khetho e nepahetseng ea lisebelisoa, ho beha maemo le ho tsamaisana, ho fokotsa liphoso le ho fokotsa litšila tsa thepa.

3.2 Sebetsa le Tlhahiso: Ka ho iketsetsa mokhoa oa ho hatisa, mechine ea CNC turret punch e eketsa tlhahiso haholo.Bokhoni ba ho etsa mesebetsi e fapaneng ntle le ho kenella ha motho ho boloka nako le litšenyehelo tsa basebetsi.Ho feta moo, bokhoni ba ho chencha lipakeng tsa likhetho tse fapaneng tsa lisebelisoa ka har'a turret bo felisa tlhoko ea liphetoho tsa lisebelisoa tsa matsoho, ho eketsa ts'ebetso.

3.3 Design Flexibility: Mechini ena e fana ka tekanyo e phahameng ea ho feto-fetoha ha moralo ka bokhoni ba ho etsa libopeho tse rarahaneng le mekhoa ea mekoti.Liphetoho tsa moralo li ka amoheloa habonolo ka ho hlophisa mochini bocha, ntle le tlhoko ea liphetoho tsa lisebelisoa tsa 'mele kapa li-setups tse ncha.

Ha re phethela:

Likhatiso tsa CNC turret punch li fetotse mokhoa oa ho hatisa.Bokhoni ba bona ba ho kopanya ho nepahala, ho sebetsa hantle le ho feto-fetoha ha moralo ho ba etsa sesebelisoa sa bohlokoahali tlhahisong ea sejoale-joale.Ka ho sebelisa mechini ena, likhoebo li ke ke tsa fumana boleng bo holimo feela le tlhahiso empa hape li ka lula li le tlholisano indastering e ntseng e fetoha ka potlako.Ho sebelisa matla a mochini oa khatiso oa CNC turret punch ke letsete le bohlale bakeng sa k'hamphani efe kapa efe e hahamallang ho ipabola tšebetsong ea tšepe le ho etsa lilakane tsa tšepe.

tlhaloso e qaqileng