A Revolutionary Duo: Mechini ea ho Kobela Metal ea Hydraulic Le Librake tsa CNC

Ha indasteri e ntse e tsoela pele ho hola, tlhoko ea mechini e tsoetseng pele e se e le ea bohlokoa.Ntho e ncha e fetolang indasteri ea tlhahiso ea tšepe ke motsoako oamechine e kobehang ka tšepe ea haeterolikile mechine e kobehang CNC.Lisebelisoa tsena tse peli tse matla li fetola tsela eo sheet metal e kobehang ka eona, e fana ka ho nepahala ho sa bonoeng, ho sebetsa hantle le ho tenyetseha.Ka poso ena ea blog, re tla hlahloba melemo le likarolo tsa duo ena e matla, e bonts'ang kamoo e ka bang letlotlo la bohlokoa indastering e 'ngoe le e' ngoe ea tlhahiso.

Matla a mochini o kobehang oa tšepe ea Hydraulic:

Mochini o kobehang oa tšepe ea haeteroliki ke sesebelisoa se feto-fetohang se etselitsoeng ho kobeha le ho etsa mefuta e fapaneng ea lisebelisoa, ho kenyeletsoa le sheet sheet.Ka matla a haeteroliki, e fana ka matla a maholo holim'a sesebediswa sa mosebetsi ho fihlela mekoloko e nepahetseng le e rarahaneng.Ebang ke ts'ebeliso ea indasteri kapa ea khoebo, mechini ena e ntlafatsa haholo boleng le lebelo la ts'ebetso ea ho kobeha lakane.

Mochini oa ho kobeha oa CNC: mohlolo oa ho nepahala:

Li-pressbrake tsa CNC, ka lehlakoreng le leng, nka ho nepahala ho isa boemong bo bocha.Mechini ena e laoloa ke thekenoloji ea taolo ea linomoro tsa khomphutha ho fana ka ts'ebetso e nepahetseng le e tsitsitseng ea ho kobeha.Ka ho hlophisa li-angles, boholo le libopeho tse ikhethileng mochining, o ka hlahisa kapele palo e kholo ea li-workpieces tsa litlhaloso tse tšoanang.Boemo bona ba ho nepahala bo felisa phoso ea motho mme bo eketsa katleho ka kakaretso mokatong oa feme.

Motsoako oa mochini o kobehang oa tšepe oa hydraulic le mochini o kobehang oa CNC:

Ha lisebelisoa tsena tse peli tse matla li kopantsoe, bahlahisi ba tla bona ntlafatso e kholo tlhahisong, boleng le ho boloka litšenyehelo.Ho kopanngoa ha mechine ea ho kobeha ea tšepe ea hydraulic e nang le li-pressbrakes tsa CNC ho lumella baetsi ba tšepe ho finyella mekoloko e rarahaneng ka mokhoa o nepahetseng ka ho fetisisa ha ba ntse ba boloka nako le boiteko.

Hlahisa ka katleho le ho boloka nako:

Ho kopanngoa ha bokhoni ba CNC mecheng ea ho kobeha ea tšepe ea hydraulic ho ka eketsa boiketsetso ba ts'ebetso ea tlhahiso.Ts'ebetso ea ho kobeha e ka iketsetsa ka ho hlophisa litekanyo tse hlokahalang le li-angles ho sistimi ea CNC.Sena ha se fokotse feela mosebetsi o hlokahalang empa hape se potlakisa haholo nako ea tlhahiso ka kakaretso.Mosebetsi o nkang nako oa ho metha ka letsoho, ho bala le ho lokisa li-angles ke ntho e fetileng.

Ho feto-fetoha ha maemo le ho feto-fetoha ha maemo:

Molemo o mong oa bohlokoa oa para ena ke ho feto-fetoha ha tsona.Motsoako oa li-brake tsa hydraulic metal press le CNC press brakes li lumella bahlahisi ho koba mefuta e sa tšoaneng ea thepa, ho akarelletsa le tšepe e sa hloekang, aluminium le tšepe ea carbon, ka boiketlo le ka mokhoa o nepahetseng.Ho feto-fetoha hona ho lumella baetsi ba tšepe ho fihlela litlhoko tsa liindasteri tse fapaneng, ho tloha ho likoloi le sefofane ho ea kahong le lisebelisoa tsa elektronike.

Ho nepahala le ho tsitsa ho ikhethang:

Ho feta moo, ho kopanngoa ha theknoloji ea CNC ho tiisa ho nepahala le ho tsitsana hohle hohle.Ka ho felisa liphoso tsa batho le ho se lumellane, bahlahisi ba ka fana ka lihlahisoa tsa boleng ho bareki.Sistimi ea CNC e etsa bonnete ba hore kobeha e 'ngoe le e' ngoe e etsoa ka mokhoa o nepahetseng ka ho fetesisa, e leng se etsang hore ho be le botsitso ho pholletsa le sehlopha.

Ha re phethela:

Ka bokhutšoanyane, motsoako oa synergistic oa mochini o kobehang oa tšepe ea haeteroliki le mochini o kobehang oa CNC o fetotse indasteri ea tlhahiso ea tšepe.Ho nepahala ho ntseng ho eketseha, ho sebetsa hantle le ho feto-fetoha ha maemo ho fanoeng ke motsoako ona ho phahamisa sekhahla bakeng sa ts'ebetso ea ho koba lakane.Lik'hamphani tsa tlhahiso ho pota lefatše joale li ka eketsa tlhahiso, tsa fokotsa litšenyehelo le ho eketsa khotsofalo ea bareki.Ha thekenoloji e ntse e tsoela pele ho fetoha, hoa thabisa ho nahana ka tsoelo-pele e eketsehileng ea ka moso mecheng ena e makatsang, e bulang tsela bakeng sa bokamoso bo khanyang ba ho etsa tšepe.

Likaroloana

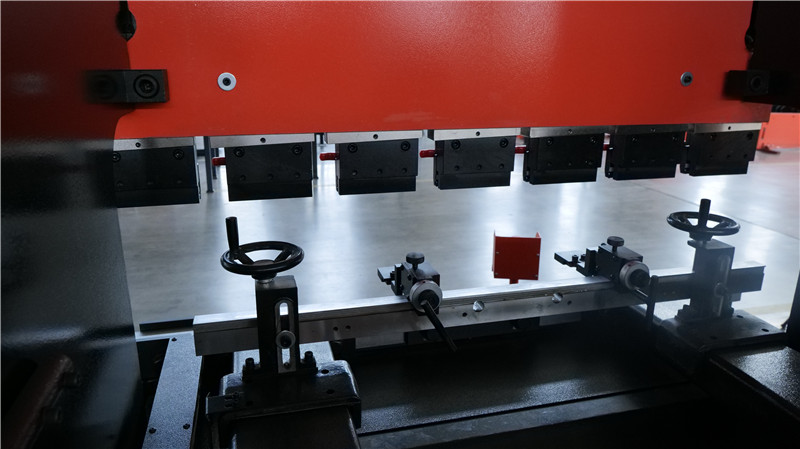

Ho Sebelisa Moepa Oa Phahamisa ho Etsa Hore ho be bonolo ho etsa Machining ea Lisebelisoa tse Khōloanyane.Sesebelisoa sa Dr/ve se Patiloe Karolong e ka Tlase ea 'Mele o ka Sehloohong oa Thepa, se Bolokang Sebaka se Pakeng tsa Liforeimi, 'me se ka sebetsa le lisebelisoa tse kholoanyane tsa ho sebetsa.

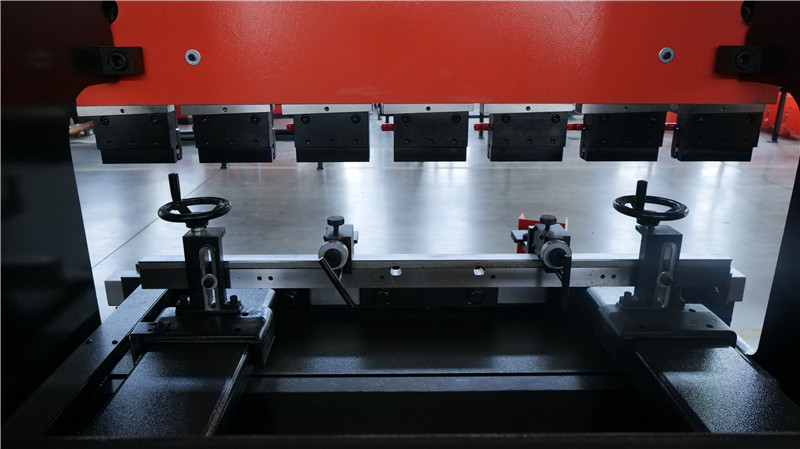

• ho sebelisa Khatello e Bohareng Ho Thibela Matla a sa Lekaneng Bohareng ba Mosebetsi

Ho Kopana le Ts'ebetso /ng Of Lihlahisoa tse phahameng tse nepahetseng.

• Nakong ea Ts'ebetso, The Worktable e tsitsitse 'me e ke ke ea sisinyeha.The Roller Guide

Mechanism e hlophisitsoe ka pele, ka morao, ka ho le letšehali le ka ho le letona ho ka tlase

Worktable, e ka Etsang Hore Worktable e tsamaee Hantle, 'me e ka Fetoha Habonolo

Lekhalo Pakeng tsa Rollers le Li-block tsa Tataiso, e le ho Fokotsa Mokhoa oa Tataiso oa ho sebetsa.

• Moralo o Molemo oa Sebopeho sa Frame o Boloka Litlhoko tse Phahameng tsa ho nepahala Esita le Ka mor'a Tšebeliso ea Nako e telele.Sebaka se ka Holimo sa Worktable se Amohela Mokhoa oa ho Lokisa Oblique Block Ho

Qoba ho sotha le D / khathatso ka har'a foreimi ea welding mme u netefatse ho nepahala ha ts'ebeliso ea nako e telele.The Micro-elastic Deformation Of Frame Nakong ea Processing Can

E-ba hantle ka pel'a sebaka sa mosebetsi.

• Moedi o Tlase Pos/tion Ya Tafole e Tlase e Behilwe ka ho Bala The Encoder Pos/tion.

Ho Des/gn ena, li-Pos/tions tse fapaneng tsa Lower Limit li ka beoa ho latela Bend e fapaneng-

Bolelele ba Bolelele, ka ho etsa joalo ho Ntlafatsa Ts'ebetso ea ho Koba.

• E Entsoe ka Mosebetsi oa Ho Kobeha oa Arc Mohato ka Mohato, 'Me Gauge ea Morao e Hatela Pele- Ward Ka Maemo a Tekano.Nako le nako ha e sisinyeha, ho etsoa Bend e le 'ngoe,' me Radian e lakatsehang 'me e kenyelelitsoe Angle e thehoa ka mor'a makhetlo a mangata a ho Kobeha.

• Mosebetsi oa ho qoba ho hula ka morao, ka ho beha Pos/tion ea Back-pull le ho lieha ho hula ka morao, mosebetsi o ka thibeloa hore o se ke oa qabana le "back stop" ka nako.

Mokhoa oa ho sebetsa ka mochini.

• Mosebetsi oa ho Bala Kakaretso ea Likotoana Tse Kobehang.

Mquick Splint e bonolo ho e sebelisa 'me e kentse kopo ea patent.

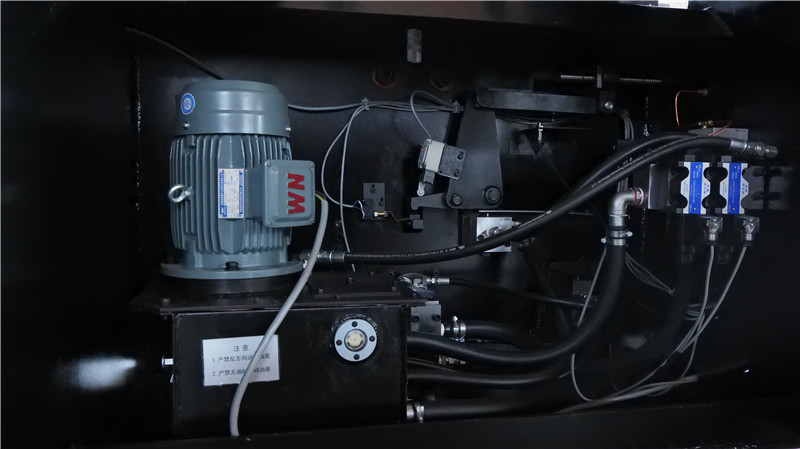

• Ha Mochini o Kobelang ka Tlase o Nyoloha le ho Kobeha, Motlakase o Khanna Pompo ea Gear ho Matla a Tsoang, 'me Ha o Theoha le ho khutla, o Lemohuoa ka Boima ba Thepa ea Mosebetsi / ka boona, 'Me Motor Idling e Boloka Matla.

• Wy-100 e Amohela Moralo oa Potoloho ea Oli ea Moqomo o le Mong oa Ma/n oa Oli le Li-cylinders tse peli tse thusang, tse ka Sebeletsang / Ze Ketso e Kopantsoeng ea Tafole e ka Tlase ea Worktable, Sephetho se sa Tšoane, 'me The Worktable Ha e Senyehe Habonolo.

tlhahiso ea lihlahisoa

| Mohlala le amanang tlhophiso | ||

| Mokhoa | WY-100 | WY-35 |

| Sistimi ea CNC | Hollysy5 | Hollysys |

| Sistimi ea servo | Panasonic/Fuj | Panasonic/Fuj |

| Sebeletsa mollo | Pangsonic/Fuj | panasonic/ Fuj |

| Matla(KN) | 1000 | 350 |

| Bolelele ba ho kobeha(mm) | 3000 | 1400 |

| Setorouku se hodimo-tlase(mm) | 100 | 100 |

| Botebo ba 'metso(mm) | 405 | 300 |

| No.Silinda | 3(1 mgin.2 Thuso) | 1 |

| Ho nyoloha lebelo la ho sisinyeha (mm/sec) | 58 | 46 |

| Lebelo la ho kobeha(mm/sec) | 10.8 | 8 |

| Lebelo le atamela(mm/sec) | 52 | 40 |

| Litekanyo tse ka holimo le tse tlase tsa baffle(mm) | 55-140 | 55-140 |

| Matla a lumelletsoeng a baffle(N) | 100 | 100 |

| Ho nepahala ha boemo ba backgauge(mm) | ±0.1 | ±0.1 |

| X axis stroke(mm) | 430 | 430 |

| X-axis max.Lebelo la ho fepa(mm/min) | 15 | 15 |

| X-axis repositioning ho nepahala(mm) | ±0.02 | ±0.02 |

| Matla a motlakase(KW) | 5.5 | 2.2 |

| Boima ba 'mele(kg | 6700 | 2200 |

| Bokhoni ba tanka ea oli(L) | 65 | 30 |

tlhaloso e qaqileng