Mochini o Kobelang oa Motlakase o Feletseng oa HPE 10031

Mekhahlelo ea mantlha ea tekheniki

| Nomoro ea letoto | Lebitso | Paramethara | Yuniti | |

| 1 | Matla a kobehang | 1000 | KN | |

| 2 | Bolelele ba tafole | 3100 | mm | |

| 3 | Karohano ea likholomo | 2600 | mm | |

| 4 | Ho teba ha 'metso | 400 | mm | |

| 5 | Bophahamo ba mmetso | 550 | mm | |

| 6 | Bophahamo ba tafole | 790 | mm | |

| 7 | Slider stroke | 200 | mm | |

| 8 | Bophahamo ba ho bula selaete | 470 | mm | |

| 9 | Lebelo la moya | 140 | mm/sec | |

| 10 | Lebelo la ho sebetsa | 50 | mm/sec | |

| 11 | Lebelo la ho kgutla | 140 | mm/sec | |

| 12 | X-axis | Setorouku | 500 | mm |

| Lebelo | 250 | mm/sec | ||

| 13 | R-axis | Setorouku | 290 | mm |

| Lebelo | 120 | mm/sec | ||

| 14 | Ho nepahala ha boemo ba X-axis

| ±0.02 | mm | |

| 15 | Matla a Y-axis servo | 28.7 | KW | |

| 16 | Boima ba 'mele | 7500 | KG | |

| 17 | Boemo: L*W*H | 3550x1650x2800 | mm | |

Sebopeho le likarolo tse ka sehloohong

Moralo le ho etsa lisebelisoa, Yangzhou Hanzhi CNC Machinery Co., Ltd. e shebana haholo le lintlha tse latelang:

Khopolo ea 'maraka ea ho phehella ho sebetsa le ho boloka sente e' ngoe le e 'ngoe bakeng sa basebelisi;

Mehopolo ea moralo e tšepahalang haholo le e nepahetseng;

Lisebelisoa tsa boleng bo holimo, likarolo tsa kantle ho naha le theknoloji e ntle ea ts'ebetso;

Ho hatisoa haholoanyane mabapi le boiketlo le polokeho ea tšebeliso le tlhokomelo;

Sekhahla sa tlhokomelo e tlase haholo le litšenyehelo tsa tlhokomelo indastering e tšoanang.

Sesebelisoa sa mochini haholo se na le foreimi, li-slide, sistimi ea ho emisa ka morao, sistimi ea taolo le hlobo, jj.

1. Frame: Karolo ena e na le litšiea tse ka ho le letšehali le ka ho le letona, poleiti ea tšehetso, tafole e ka tlaase le likarolo tse ling tsa foreimi e bōpehileng joaloka lebokose.Bethe e tšeloa ka poleiti ea tšepe ka kakaretso, 'me ka mor'a ho cheselletsa, mochine o kenngoa mocheso o phahameng oa ho tsofala ka likhato tse 700 bakeng sa lihora tse 24,' me bokaholimo bo tšoaroa ka ho phatloha ha lithunya, ho felisang ka ho feletseng khatello ea ka hare e hlahisoang nakong ea ho tjheseletsa. e amohela moralo o boima ho netefatsa ho tiea le botsitso ba nako e telele ea sesebelisoa sa mochini.

2. Slider: Karolo ena haholo-holo e na le slider, lebokose la matla, sekala sa makenete, sekoti, seporo sa tataiso ea khutlonnetsepa le likarolo tse ling.Lebokose la matla le letšehali le le letona le nang le liboutu le khokahanyo ea foreimi, screw le slider ho sebelisa linate, khokahano ea li-ball block, sebopeho sa slide se ka ntlafatsa bophelo ha se le tlas'a mojaro o sa fellang.The slider le foreime li hokahane ka rectangular tataiso seporo.Seporo sa seporo sea itlholisa, 'me ho hlokahala marotholi a seng makae feela a oli beke le beke.Ka foreiming ka mahlakoreng a mabeli a poleiti e nang le sebopeho sa C e nang le sekala ho laola boemo bo ka holimo ba moeli oa sekhahla sa slider, boemo bo tlase ba moeli, stroke e se nang letho le ho sebetsa ha sebaka sa phetoho, hammoho le ho lemoha, maikutlo. ya motsamao o hokahaneng wa dikurufu tse pedi.

3. Sistimi ea ho laola: Ho amohela mokhoa o ikemetseng oa ho laola lipalo, ho latela botenya ba poleiti, thepa, bolelele le lipalo tse ikemetseng tsa matla a kobang, ho bala ka mokhoa o itekanetseng oa tokiso ea phoso ea angular.

4. Hlobo: Karolo ena e na le likarolo tse peli: kopano e ka holimo ea hlobo le kopano e ka tlaase ea hlobo.Hlobo e ka holimo e behiloe holim'a slide, e itšetlehile ka poleiti ea clamping ho e lokisa, hlobo e ka tlaase e ka ba V e le 'ngoe, V habeli le V le mefuta e meng, hlobo e ka aroloa ho ea ka litlhoko tsa mosebedisi.

5. Tšehetso ea lijo tse ka pele: Karolo ena ke karolo e tloaelehileng, e kentsoeng ka pele ho tafole e sebetsang.Ha u sebelisa, ho ea ka bolelele ba mosebetsi, sets'oants'o sa pallet se ka pele se ka isoa ka letsoho ho ea sebakeng se loketseng bakeng sa ho tiisa, mochine oa pallet o ka fetoloa ka holimo le ka holimo.

Sebopeho sa sehlahisoa le sebopeho

1. Yangzhou Hanzhi moralo o ikemetseng, ponahalo e ntle, e entsoeng hantle.

2. Mohaho oohle oa tšepe oa tjheseletsa, foreimi e teteaneng, ho tiea le ho monya ho ts'oha.

3. Likarolo tsa mohaho li fokotsehile ka ho silafatsoa le ho fafatsoa ka pente ea antirust.

4. Kholomo, li-slide tse sebetsang ka holimo le tafole e ka tlaase ea mochine oa mochine li phethoa ke lefats'e le tsoetseng pele le leholo la CNC fatše le boring le mochine oa ho sila, o tiisang hore ho tšoana, perpendicularity le parallelism ea sebaka se seng le se seng se ntseng se phahama.

5. Moralo o matla oa ho kobela holimo o boreleli, o bonolo ebile o bolokehile ho sebetsa.

6. Setsing se ka tlaase se shoeleng, ho na le mosebetsi oa ho lieha ho boloka khatello ho netefatsa ho nepahala ha workpiece.

7.Tlas'a maemo a litekanyetso tsa naha kapa tsa machaba, ho nepahala ha angle ea ho khumama ho tiisetsoa ka hare ho ± 0.5 degrees.

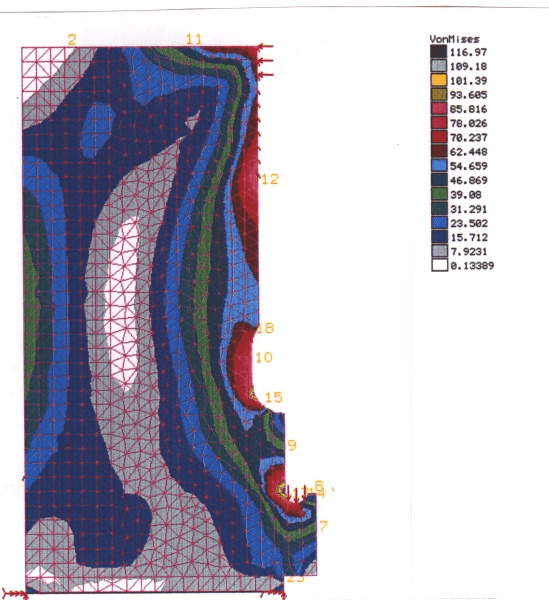

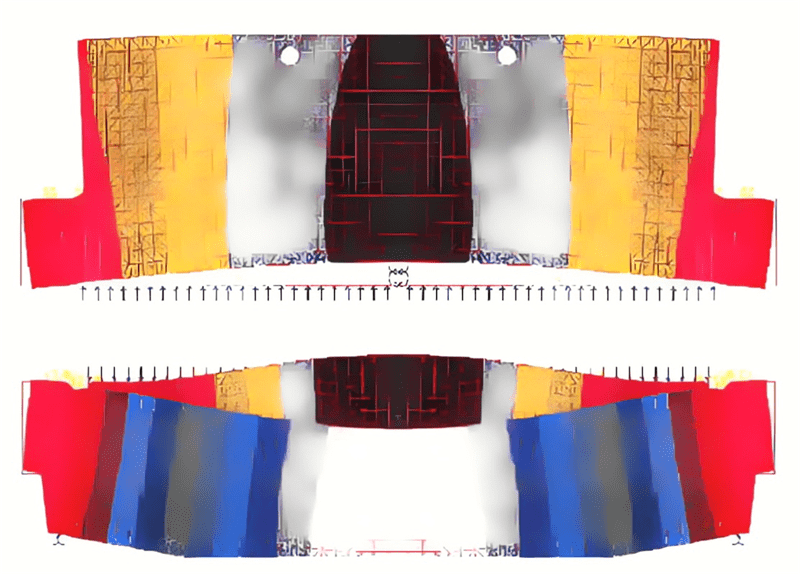

Mochini o entsoe ho sebelisoa tlhahlobo ea lintlha tse fokolang

Sistimi ea matšeliso ea ho kheloha

Bed deformation curve ea finite element analysis

Sistimi ea matšeliso ea ho kheloha e tiisa hore tafole le slide e ka holimo li lula li tšoana nakong ea ts'ebetso ea ho kobeha.

Botenya ba Sheet, bolelele, ho buloa ha hlobo e tlase le data ea matla a thata li kenngoa tsamaisong ea CNC, matla a ho khumama le tafole e lumellanang le slide offset e kaholimo e baloa ka bo eona, ts'ebetso e 'ngoe le e' ngoe ea ho khumama e tla laoloa ke sistimi ea CNC ho lokisa puseletso ea ho kheloha mochini. mokhoa oa ho fihlella boemo bo loketseng ba leqhubu.Sistimi e fana ka bokhoni ba ho itokisa le ho iphetetsa ka boiketsetso, e ka khonang, ka ts'epahalo le ka nepo ho lokisa mothinyeho oa tafole ka bolelele bohle ho ts'oana le curve ea deformation e le ho etsa hore bolelele bohle bo ts'oane.Mochini o amohela sistimi e tsoetseng pele ea matšeliso ea ho kheloha ho netefatsa ho otloloha ha sesebediswa sa mosebetsi.

Matšeliso a mochini: e na le li-block tsa mats'eliso a holimo le a tlase, a entsoeng ka libaka tse tharo-dimension tse nang le matsoapo a fapaneng ho ea ka mapheo a kheloha a slide le tafole, 'me mothinya oa mats'eliso o haufi le maqhubu a kheloha a sereledi. tafole, e leng se etsang bakeng sa letheba foufetseng ea matšeliso haeteroliki, 'me kahoo haholo ntlafatsa machining ho nepahala ha mochine oa khatiso oa brake,' me e bitsoa puseletso kakaretso ha ho bapisoa le matšeliso haeteroliki.

Melemo ea matšeliso a mochini:

Matšeliso a mechine a lumella matšeliso a nepahetseng a ho kheloha ka bolelele bo feletseng ba tafole.Matšeliso a ho kheloha ha mechine a fana ka botsitso ba nako e telele 'me ha a na tlhokomelo bophelong bohle ba mochine.

Matšeliso a ho kheloha ka mechine, ka lebaka la palo e kholo ea lintlha tsa matšeliso, e lumella mochine oa ho koba hore o kobe mochine oa mosebetsi ka tsela e hlakileng haholoanyane, e leng ho ntlafatsang phello ea ho khumama ea workpiece.

Matšeliso a mechine ke tšebeliso ea potentiometer ho lekanya boemo ba pontšo ea ho khutla, e le setsi sa CNC, ho finyella taolo ea digital, e le hore boleng ba matšeliso bo nepahetse haholoanyane.

litšobotsi tsa mochine

Leeto la screw ke 200mm mme botebo ba 'metso ke 400mm, e leng se ntlafatsang haholo mefuta ea ts'ebetso ea likarolo tsa sehlahisoa, ha tafole e ka tlaase e nka mokhoa oa matšeliso oa mochine.

tlhaloso e qaqileng