Panel e ikemetseng Bender HMBC2202-2203

tlhahiso ea lihlahisoa

| Che. | Lebitso | Paramethara | Yuniti |

| 1 | Bolelele | 2200 | mm |

| 2 | Max.bophara | 1500 | mm |

| 3 | Min.Bolelele ba ho kobeha | 130 | mm |

| 4 | Min.e kobehang bophara | 240 | mm |

| 5 | Botenya ba Max.bending ( MS , UTS410N/mm² ) | 2 | mm |

| 6 | Min.bending thick ( MS , UTS410N/mm² ) | 0.35 | mm |

| 7 | Boemo bo phahameng | 200 | mm |

| 8 | Mokhoa oa ho fetola bolelele ba mochine o ka holimo | Ka ho iketsa | |

| 9 | Karolelano ea tšebeliso ea matla | 4 | KW |

| 10 | Boholo ba pono: L*W*h | 6100 * 2700 * 2920 | mm |

tlhahiso ea lihlahisoa

| Che. | Lebitso | Paramethara | Yuniti |

| 1 | Bolelele | 2200 | mm |

| 2 | Max.bophara | 1500 | mm |

| 3 | Min.Bolelele ba ho kobeha | 430 | mm |

| 4 | Min.e kobehang bophara | 350 | mm |

| 5 | Max.bending botenya ( Stainless steel , UTS660N/mm) | 1.8(+-90 °) | mm |

| 6 | Max.bending botenya (tšepe,UTS410N/mm) | 3(+-90 °) | mm |

| 8 | Min.bending botenya ( aluminium , UTS120N/mm) | 0.35 | mm |

| 9 | Boemo bo phahameng | 300 | mm |

| 10 | Mokhoa oa ho fetola bolelele ba mochine o ka holimo | Ka ho iketsa | |

| 11 | Karolelano ea tšebeliso ea matla | 12 | KW |

| 12 | Boima ba 'mele | 32 | T |

| 13 | Boholo ba pono: L*W*h | 6300*5500*3300 | mm |

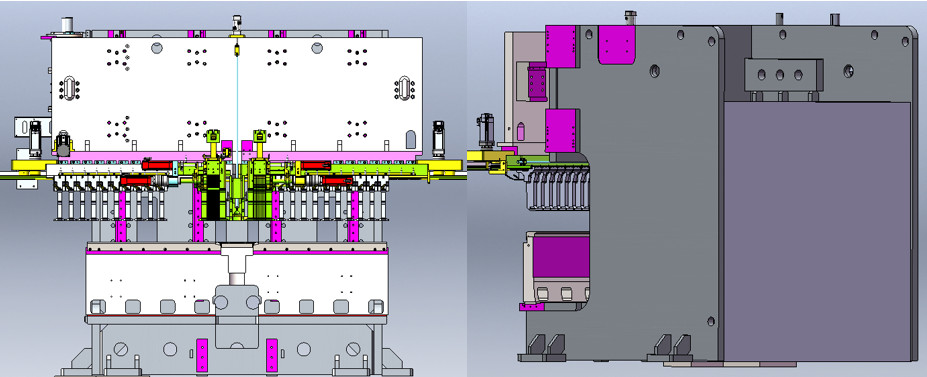

Litšobotsi le sebopeho se seholo

Mabapi le moralo oa mochini le tlhahiso, He Bei Han Zhin CNC Machinery Co.,Ltd.e shebana haholo le lintlha tse latelang:

1.Mohopolo oa 'maraka oa ho phehella ho sebetsa le ho boloka chelete bakeng sa basebelisi;

2.Mehopolo ea moralo e tšepahalang haholo le e nepahetseng;

3.Lisebelisuoa tse tala tsa boleng bo phahameng, likarolo tse tsoang ka ntle le theknoloji e tsotehang ea ho sebetsa;

4.Hatello e eketsehileng holim'a boiketlo le polokeho ea tšebeliso le tlhokomelo;

5.Sekhahla se tlaase sa tlhokomelo le litšenyehelo tsa tlhokomelo indastering e tšoanang.

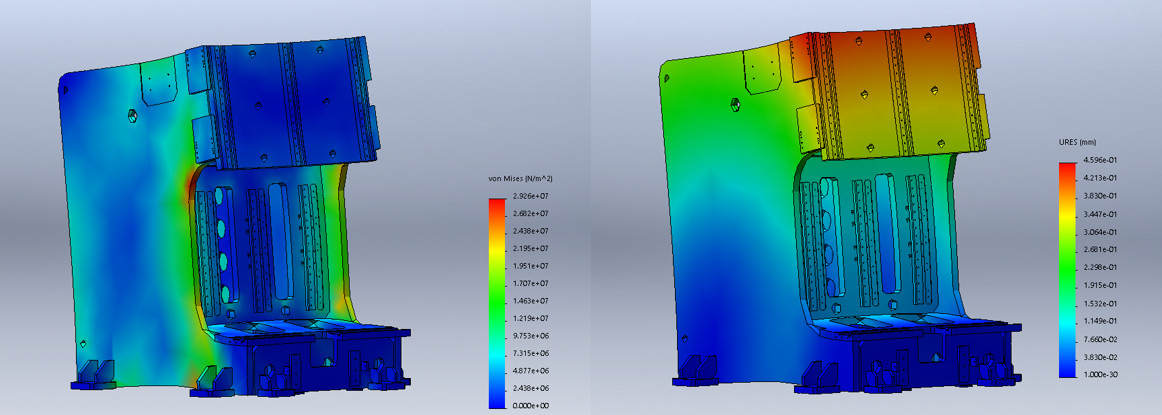

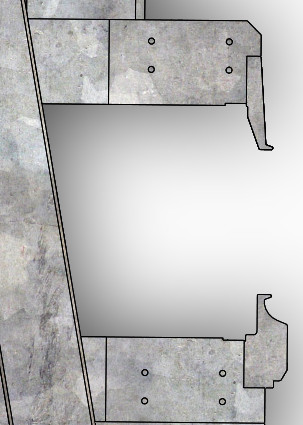

foreimi

A. Theha mohlala oa likarolo tse tharo tse lekanyelitsoeng: ho latela mohlala o tiileng oa mahlakore a mararo o ntlafetseng le o entsoeng, theha mofuta oa finite element dynamic model bakeng sa lipalo.Mohlala o nahana ka likarolo tse kholo mabapi le khokahano ea phetisetso ea matla.Matla a fetisetsoa ho ts'ehetso ka likarolo tse kopanyang, ebe joale tlhahlobo ea matla ea tšehetso e etsoa.

B. Tlhahlobo ea liphetho tsa tlhahlobo ea static: ka lebaka la lebelo le liehang la ho sebetsa, tlhahlobo ea matla e ka bakoa ke mathata a tsitsitseng.Ho ea ka poleiti e hatellang mojaro le mojaro o kobehang ka tataiso e otlolohileng ea hlooho ea sehahi, khatello ea maikutlo le liphetho tsa deformation li bonts'oa setšoantšong se ka tlase.Khatello e phahameng ea khatello e hlaha molaleng oa fuselage, khatello e phahameng ea khatello ke 21.2mpa, ho fokotseha ho hoholo ho hlaha karolong e ka holimo ea fuselage, 'me ho senyeha ho hoholo ke 0.30mm.

Ho ea ka liphetho tsa tlhahlobo ea likarolo tse fokolang tsa foreimi, tšepe ea Q345 e khethoa e le thepa;Carbon dioxide e sireletsa tjheseletsa;Etsa kalafo ea tempering ho felisa khatello ea maikutlo e bakoang ke welding;E le ho netefatsa ho nepahala, botsitso le ho tiea ho hoholo ha lisebelisoa bakeng sa ts'ebetso ea nako e telele.

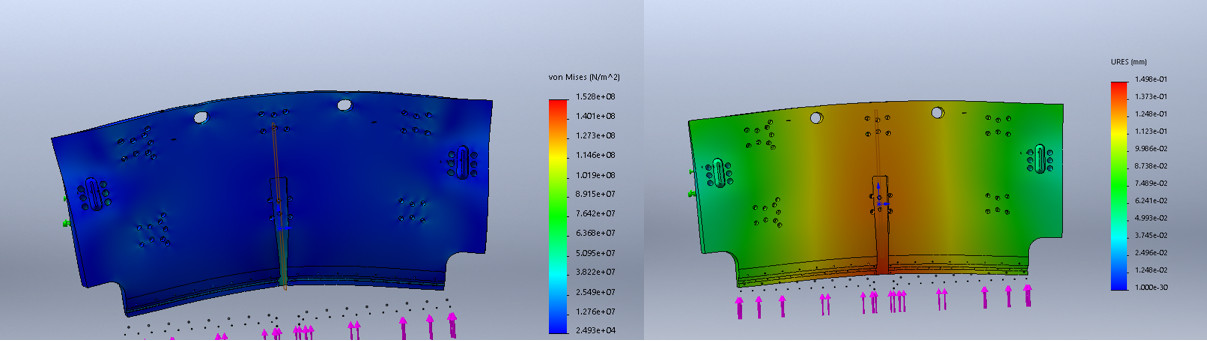

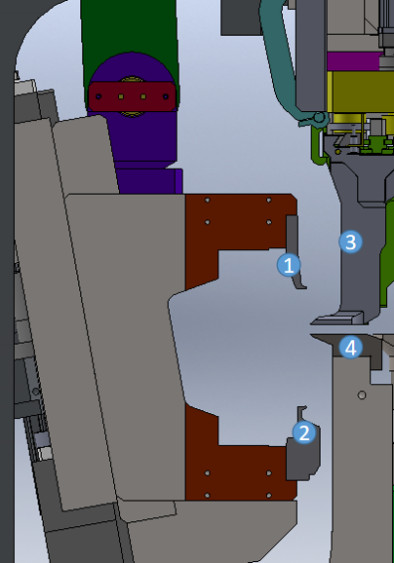

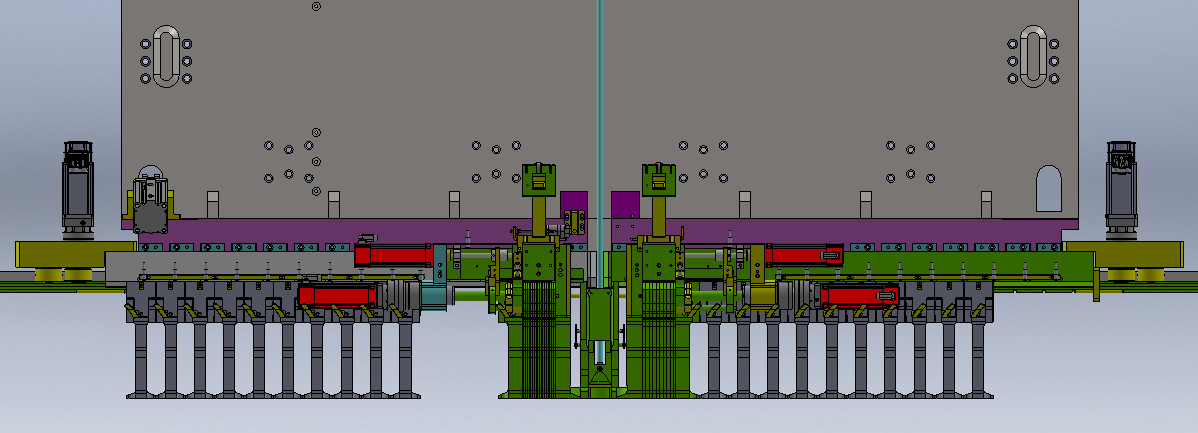

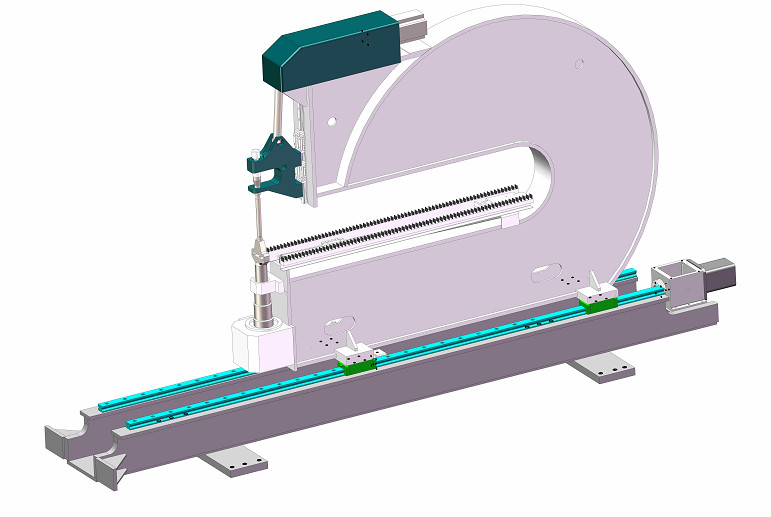

Pheleu e ka hodimo

Karolo ena haholo-holo e entsoe ka rama, torque lead screw, reducer, guide rail, servo motor, joalo-joalo Motlakase o ka sehloohong o laoloa ke servo motor, 'me mokhoa oa ho laola ke servo synchronous control, e ka netefatsang ho nepahala ha boemo, ka potlako. lebelo le taolo e phahameng.Ho tlotsoa ha sekoti sa lead le seporo sa tataiso ho amohela lubrication ea othomathike, 'me grease ke 00#, e le ho netefatsa bophelo ba ts'ebeletso le ho nepahala ha sekoti sa lead le seporo sa tataiso bakeng sa ts'ebetso ea nako e telele.

Tlhahlobo ea liphetho tsa tlhahlobo e tsitsitseng ea slider e kaholimo: nephogram ea khatello ea maikutlo ea tafole e holimo e bonts'a hore khatello e phahameng ea khatello ea maikutlo e hlaha kaholimo ho karolo e kaholimo, khatello e phahameng ea khatello ke 152mpa, deformation e phahameng e hlaha pheletsong e kaholimo ea karolo e kaholimo. worktable, 'me deformation palo e kahodimodimo ke 0.15mm

Ho ea ka liphetho tsa tlhahlobo ea likarolo tse fokolang tsa pheleu, tšepe ea Q345 e khethoa e le thepa;Carbon dioxide e sireletsa tjheseletsa;Etsa kalafo ea tempering ho felisa khatello ea maikutlo e bakoang ke welding;E le ho netefatsa ho nepahala, botsitso le ho tiea ho hoholo ha lisebelisoa bakeng sa ts'ebetso ea nako e telele.

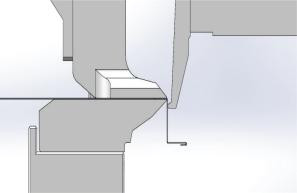

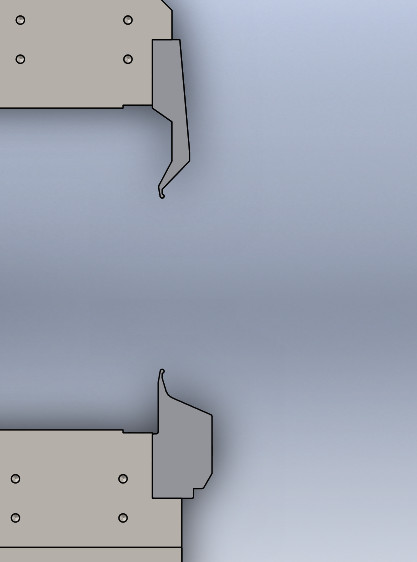

Yuniti e kobehang

Karolo e tsamaisang matla ea mochine o kobehang e tsamaisoa ke servo motor ntle le ho kenya letsoho tsamaisong ea hydraulic, e nang le melemo e mengata ea ho fokotsa ts'ebetso ea likarolo le ts'ebetso ea phetisetso, 'me e lumellana le leano la ho boloka matla le ho sireletsa tikoloho le buelloang ke naha.

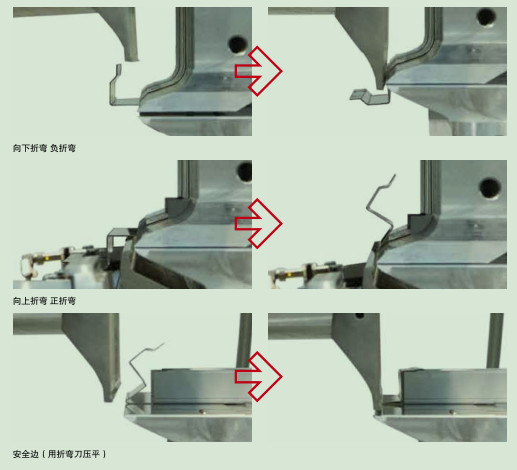

Ho ea ka boemo ba tlhahisoleseding ea poleiti, tsamaiso ka boeona e lekanya boemo ba thipa e ka holimo ea ho hatella 3, e laola sebaka se pakeng tsa thipa e ka holimo ea 3 le thipa e tlaase ea 4, 'me e lokisa poleiti;Ho ea ka tsamaiso ea tsamaiso, ho sa tsotellehe hore na ho khumama hona ho ea holimo kapa ho ea tlaase, laola thipa e kobehileng e tlaase 2 kapa thipa e kobehang e ka holimo 1 ho tsamaea ka potlako ho ea boemong ba ho khumama;Ho ea ka li-angles tse fapaneng tsa tlhophiso, foromo ea palo e nang le tokelo ea molao e laola punch e kobehang ho ea sebakeng sa lipalo ho phethela ho kobeha.

Ho latela mekhoa e fapaneng ea ho kobeha, e ka aroloa ka ho kobeha ka mahlakoreng, ho kobeha ho hoholo, ho kobeha ha li-arc, joalo-joalo har'a tsona, ho kobeha ha angle ho boetse ho arotsoe ka ho kobeha holimo le ho theohela tlaase.

Setsi sa khatiso se holimo

Upper pressing unit: karolo e lokelang ho sebelisoa ts'ebetsong eohle ea ho kobeha.HMBC full servo multilateral bending center e na le mochine o khethehileng oa khatiso o ka holimo, o ka kenngoa le ho fetoloa ka bohona ho latela bolelele bo fapaneng ba poleiti.

Sesebelisoa

Lisebelisoa tsa ho kobeha li arotsoe ka lisebelisoa tse kobehang ka holimo le lisebelisoa tse kobehang tse tlase.Lisebelisoa tse khethehileng tsa ho koba li ka etsoa ho latela litlhoko tse fapaneng tsa bareki.

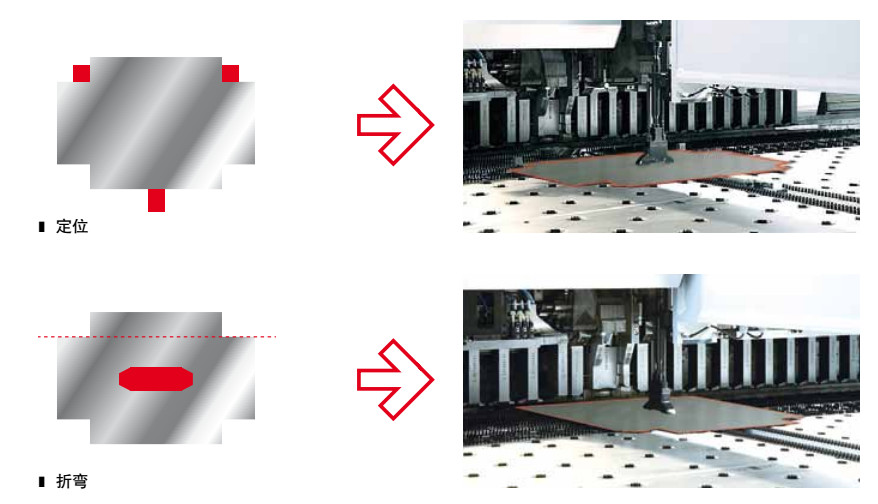

2.Setsi sa ho fepa ka poleiti:

Ho sisinyeha, ho koala le ho potoloha ha tšepe ea lakane ho laoloa ke manipulator 1, clamp 2 le disc e potolohang 3 ka ho latellana.Phepelo ea tšepe ea sheet e laoloa ke servo motor ts'ebetsong eohle ea ts'ebetso, e le ho lemoha boiketsetso le boemo bo potlakileng, ho fokotsa nako ea ts'ebetso le ho ntlafatsa ts'ebetso.Ka lebaka la boqapi ba sebopeho le ts'ebeliso ea taolo e felletseng ea servo, ts'ebetsong eohle ea setsi sa ho kobeha sa linaha tse ngata, ho koala le ho potoloha ha tšepe ea lakane ho ka boloka ho nepahala.Bakeng sa lisebelisoa tse ngata tse rarahaneng esita le li-workpieces tsa polygonal, ho nepahala ho tsoelang pele ho potoloha ho ka netefatsoa ho ba 0.001.

3.Plate positioning unit :

Pini e behang poleiti e entsoe ka phini e behang ka ho le letšehali, phini e behang ka ho le letona, phini e behang ka pele le phini e behang ka morao;Lithakhisa tse behang ka ho le letšehali le ka ho le letona li ka fumana libaka tse ka ho le letšehali le tse ka ho le letona tsa poleiti.Pini e behang ka pele le phini e behang ka morao li laola maemo a ka pele le a ka morao a poleiti ho netefatsa hore poleiti e bapa le lithipa tse hatellang holimo le tlase, tse sebelisoang ho netefatsa boemo bo nepahetseng ba poleiti.

The poleiti boemo yuniti ka tlatsa boemo jarolla ka ho iketsa ea poleiti 'me ka tsela e iketsang tlatsa kobang multilateral ka nako e le' ngoe, e leng khutsufatsa haholo nako ea ho kobeha potoloho le ho laola ho kuta phoso poleiti ka kobang pele ho etsa bonnete ba ho nepahala ha kobang.

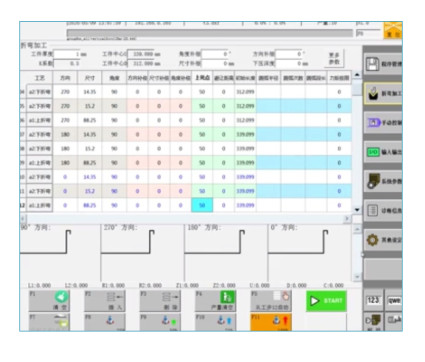

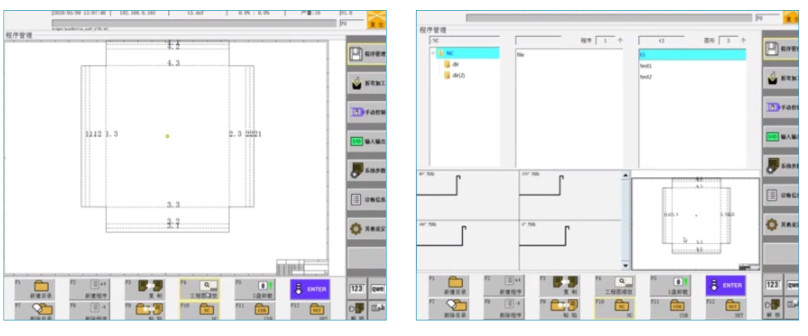

4.CNC tsamaiso

A: Sistimi ea CNC le software e ntlafalitsoeng ka kopanelo e ka sebelisoa le ho laoloa kapele le ha bonolo

B: Lintlha tse ka sehloohong:

a) .Mokhoa oa ho laola libese oa EtherCAT o amohetsoe, o nang le bokhoni bo matla ba ho thibela tšitiso

b) Ts'ehetsa mananeo a tobileng le data e kobehang ea mohato o mong le o mong ka foromo

c) Tšehetsa arc kobehang

d) Taolo e felletseng ea servo ea motlakase

e) Ts'ehetsa ts'ebetso ea puseletso e kobang

f) Tšehetsa tšebetso ea mananeo a mahlakore a mabeli

Ts'ebetso ea mananeo a mahlakore a mabeli, e kenya data ea ho taka ea DXF ea mahlakore a mabeli, 'me e iketsetsa mokhoa oa ho kobeha, boholo ba ho kobeha, angle e kobehang, angle ea ho potoloha le lintlha tse ling.Kamora ho netefatsoa, ts'ebetso ea ho kobeha ka boiketsetso e ka etsoa

Lethathamo la karolo e kholo

| Che. | Lebitso | Brand |

| 1 | Foreimi | Bohlale |

| 2 | Sesebelisoa | Bohlale |

| 3 | Yuniti e kobehang | Bohlale |

| 4 | Sistimi ea CNC | Bohlale |

| 5 | Servo motor | Bohlale |

| 6 | Mokhanni oa servo | Bohlale |

| 7 | Seporo | Bohlale |

| 8 | Ballscrew | Bohlale |

| 9 | Mofokotsi | Taiwan |

| 10 | Seqhenqha | Schneider |

| 11 | Konopo | Schneider |

| 12 | Karolo ea motlakase | Schneider |

| 13 | Cable | Yicu |

| 14 | switjha e haufi | Omron |

| 15 | Bearing | SKF/NSK/NAICH |

4) Moralo, ho etsa, ho hlahloba le ho kenya sesebelisoa sa mochini ho fihlela litekanyetso tse latelang.

1, GB17120-1997

2, Q/321088JWB19-2012

3, GB14349-2011

Karolo e setseng le lenane la lisebelisoa

| Che. | Lebitso | Qt. | Ela hloko |

| 1 | Lebokose la lisebelisoa | 1 | |

| 2 | Kenya pad | 8 | |

| 3 | Sepane sa ka hare sa hexagon | 1 sete | |

| 4 | Sethunya sa ho tlatsa mafura ka letsoho | 1 | |

| 5 | Buka ea tsamaiso ea CNC | 1 | |

| 6 | sepane se bulehileng | 1 |