Tsebisa

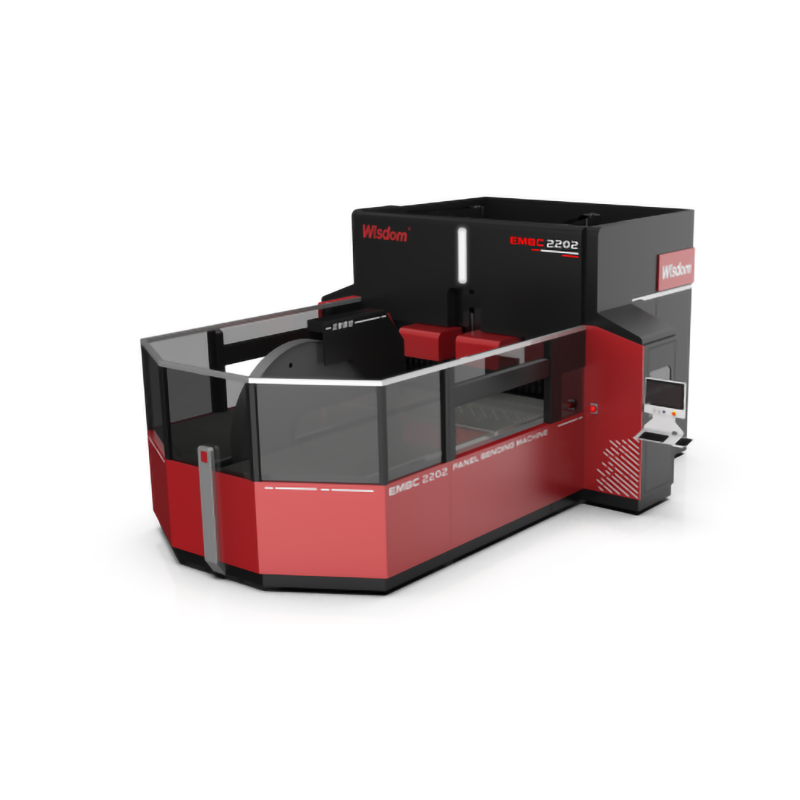

Tlhahisong ea indasteri, ho nepahala le ho sebetsa hantle li bohlokoa.Tlhokahalo e sa khaotseng ea liphetho tse phethahetseng, haholo ha o sebetsa ka lisebelisoa tse kang liphanele tsa aluminium, e lebisitse ho nts'etsopele ea mechini e tsoetseng pele.Kajeno, re kenella ka har'a matla a ho fetola aMechini e kobehang ea liphanele tsa CNC, tse fetotseng tsela eo poleiti e kobehang ka eona.Ka sengoloa sena, re ikemiselitse ho hlahloba likarolo, melemo le ts'ebeliso ea mechini ena e tsoetseng pele.

Ho nepahala ho fetisisa

Mechini e kobehang ea tšepe ea maqepheesale e le sesebelisoa sa bohlokoa indastering ea tlhahiso.Leha ho le joalo, ho hlahisoa ha theknoloji ea CNC (taolo ea linomoro tsa khomphutha) ho nkile ho kobeha ka nepo ho isa boemong bo bocha.Mechini e kobehang ea CNC e fana ka othomathike e makatsang, e lumellang taolo e nepahetseng ea mohato o mong le o mong oa ts'ebetso ea ho kobeha.Mochini o khona ho bala le ho etsa mekhoa e rarahaneng ea ho koba ka nepo e phahameng, ho tlosa phoso e kileng ea qojoa ea motho.Ka lebaka leo, bahlahisi ba ka finyella li-bends tse tsitsitseng, tsa boleng bo phahameng ba aluminium tse fetang bokhoni ba li-brake tsa khale tsa khatiso.

Nolofatsa mokhoa ona

E 'ngoe ea melemo ea bohlokoa ka ho fetesisa ea mechini e kobehang ea CNC ke bokhoni ba bona ba ho nolofatsa mokhoa oa ho koba lakane.Mechini ena e kopanya tšebetso eohle ea ho kobeha, ho kenyelletsa ho kenya, ho kobeha le ho laolla, ho sistimi e le 'ngoe e ikemetseng.Sena se felisa tlhokahalo ea mechine e mengata kapa mosebetsi oa matsoho, ho eketsa tlhahiso le ho fokotsa nako ea tlhahiso.Ka ho fokotsa ho kenella ha batho, bahlahisi ba ka eketsa tlhahiso ha ba ntse ba boloka litekanyetso tse ntle tsa boleng.

Ho notlolla bokhoni ba aluminium

Aluminium ke thepa e sebelisoang haholo ho pholletsa le liindasteri ka lebaka la boima ba eona bo bobebe, bo tšoarellang le ho feto-fetoha ha maemo.Ka lebaka la litšoaneleho tsa eona tse ikhethang, mechine ea khale ea ho kobeha ea tšepe hangata e tobana le mathata ha e sebetsa aluminium.Leha ho le joalo, metjhini e kobehang ea liphanele tsa CNC e butse tsela ea ho fihlela mekokotlo e rarahaneng ntle le ho senya botšepehi ba liphanele tsa aluminium.Taolo e nepahetseng ea thekenoloji ea CNC e tiisa hore ho kobeha ha boleng bo holimo, ho tlisa maemo a mangata le katleho indastering ea aluminium.

Ho feto-fetoha ha maemo le ho ikamahanya le maemo

Mechini e kobehang ea lakane ea CNC e fana ka maemo a ikhethang le ho ikamahanya le maemo, ho etsa hore e be tse loketseng lits'ebetso tse fapaneng.Mechini ena e khona ho sebetsana le mefuta e mengata ea likobe ho tloha ho tse bonolo ho ea ho tse rarahaneng, ho ikamahanya le meralo le merero e fapaneng.Ho sa tsotellehe hore na ho etsa mekotla ea motlakase, likarolo tsa likoloi kapa lipontšo, mechine e kobehang ea CNC e ka ikamahanya le mefuta e fapaneng ea li-angles le radii, ho netefatsa hore tlhahiso ea fetoha.Ka litsamaiso tse tsoetseng pele tsa taolo, basebelisi ba ka fetola habonolo lipakeng tsa mesebetsi, ba eketsa ts'ebetso le ho fokotsa nako ea ho theoha.

Amohela bokamoso

Ho hlaha haMechini e kobehang ea CNCe hlalositse bocha mokhoa oa tlhahiso ea indasteri.Ho nepahala ha bona, ho iketsetsa le ho feto-fetoha ha maemo ho etsa hore e be letlotlo la bohlokoahali indastering e kang ea sefofane, likoloi le kaho tse hlokang liphetho tse se nang sekoli.Ha theknoloji e ntse e tsoela pele, ho lebelletsoe hore mechini ena e tla ntlafatsoa le ho feta ho fihlela litlhoko tse fetohang tsa indasteri.

Ha re phethela

Ho nepahala, ho sebetsa hantle le ho feto-fetoha ha maemo ke metheo eo ho eona li-brake tsa CNC li fetolang tlhahiso bocha.Ka ho kopanya matla a othomathike le ho nepahala ha thekenoloji ea CNC, metjhini ena e notlolla menyetla e mecha ea ho kobeha ha phanele, haholo-holo machining a aluminium.Ha re ntse re amohela bokamoso, ho na le bonnete ba hore mechini e kobehang ea CNC e tla tsoela pele ho fetoha, e lumella bahlahisi ho fihlela maemo a sa lebelloang a ho nepahala, tlhahiso le boqapi.

Nako ea poso: Nov-10-2023